| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ESİT ELEKTRONİK ANONİM ŞİRKETİ

Yeni Sanayi Yolu Üzeri Yeşiloba Mah. Atikop İş Merkezi 3. Blok No: 2 Seyhan / / ADANA / TÜRKİYE

|

Contact Info: +903224281171

|

Hall: 1

Stand: 400D

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Esit Elektronik, with production facilities in Istanbul Çekmeköy and Sakarya Hendek, manufactures load cells, weighing indicators, and dynamic weighing devices in Istanbul, while Hendek hosts Europe s largest truck scale factory. Offering both components and complete weighing solutions such as bag filling, belt and hopper scales, Esit is among the few global brands serving diverse industries. Headquartered in Istanbul since 1980, Esit pioneered European-standard automatic weighing devices in the 1990s, expanded exports and certifications in the 2000s, and launched its major Hendek factory in 2010. Today, beyond manufacturing, Esit develops engineering and software solutions, delivering products and services through Turkey s most extensive network and exports to over 60 countries worldwide.

The TARIMSU platform offers a complete management experience through both its mobile application and cloud infrastructure. Farmers and organizations can manage their irrigation operations right at their fingertips. Moving away from traditional methods, irrigation processes and amounts are optimized through real-time, AI-powered, data-driven decisions. With instant notifications based on real-time field data and remote control capabilities, the platform provides full operational flexibility.

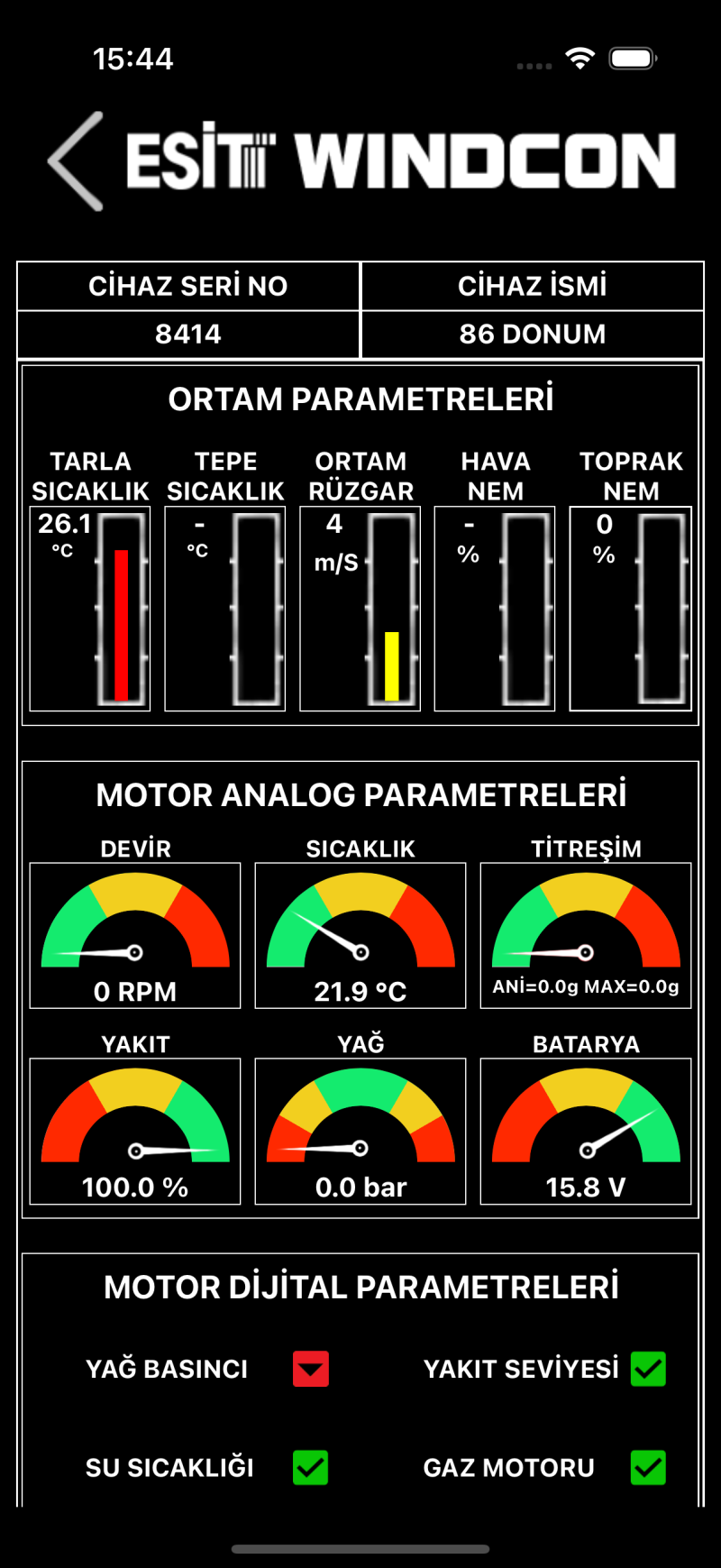

The Esit WINDCON application is a control and monitoring tool designed to operate on mobile devices for Esit WM systems. Through the app, users can add an unlimited number of motors and remotely monitor them, accessing both real-time and historical data for each motor and its environmental parameters. Error reports and alarms related to the motor and fan are automatically sent to the user by the application.

The new Esit ECI Filling Indicator offers functionality, performance, and ease of use far beyond industry standards with its upgraded hardware, bright display, and advanced software structure. Designed for panel mounting, the Esit ECI features an IP65-rated front panel with a touch keypad and a new bright graphic display that clearly visualizes the weighing process through various alerts and visuals. Equipped with a standard USB port, the Esit ECI provides built-in functions such as free software updates, data backup, and reporting.

Esit WM is an advanced motor control system to operate wind generator engines. The system is designed specifically to prevent agricultural products loss due to freezing temperatures.

BIG-BAG filling systems are used in bagging of bulk material in granule and powder form, reducing the bagging, conveying and storing costs in great amounts. In a way they are green systems in environmental manner. Increasing the bag volume from 25-50kg to 500kg or 1-2tons, the production and stocking capacity is increased. Esit Big-Bag filling systems are produced in a broad line starting from manual filling, going till automatic filling, dust capturing and re-using units. For very fine powder type of materials, double covered Big- Bag sacks, special production can also be done. Varying of the customer needs, material supply or turn-key projects can be accomplished. The system consists of mainly the flow control part-helix-vibrator, belt, double position lid etc., Bag capturing mechanism, bag inflation, dust collection, aspiration, weight measuring unit-indicator, load cell, control panel, main carrying mechanical construction, pneumatic pistons and valves. The system is designed according to the type of Big-Bag used in the site. In various environments such as PVC, cement, raw mine, borax PP (polypropylene) PTA (pretrephtalic acid), AYPE, YYPE (polyethylene), PS (polystren) etc.

Valve bag filling machines are used for filling products in powder form (cement, gypsum, grout, calcite etc.) other powder materials, into bags with valves. There are models with single or multiple filling outlets depending on the production capacity. The system performs bagging operation depending on the quantity set (target material) by the user. The system is composed of a control panel and mechanical parts. After starting the system, fast and slow filling processes take place in order. After filling, bag knock over piston releases the bag. In the triple system, the bags in 2. and 3. weighing areas are waited for the parametric knock over periods set in PLC program in order to prevent dropping of the bags one over another.

Esit BF Bagging Scales are bagging machines used for filling bulk material into bags with the weight of 10-50 kg. It automatically starts operation after the operator inserts the bag to the filling outlet, it fills the bag with the set quantity accurately in two stages and releases it when filling finishes. The operation continues subsequently. Sewing belt is optional. Esit BF Bagging Scale is microprocessor controlled and full electronic. It is possible to obtain quantity and weight reports related to the bags filled and to connect other electronic devices such as PLC and computers. Valve and filling outlet structure are selected depending on the type of the good. It is used for bagging materials such as legumes, granular materials, salt, granular chemicals, pulp, animal feed, grains, cement, construction chemicals, coal, stone and corn.

Esit BF Bagging Scales are bagging machines used for filling bulk material into bags with the weight of 10-50 kg. It automatically starts operation after the operator inserts the bag to the filling outlet, it fills the bag with the set quantity accurately in two stages and releases it when filling finishes. The operation continues subsequently. Sewing belt is optional. Esit BF Bagging Scale is microprocessor controlled and full electronic. It is possible to obtain quantity and weight reports related to the bags filled and to connect other electronic devices such as PLC and computers. Valve and filling outlet structure are selected depending on the type of the good. It is used for bagging materials such as legumes, granular materials, salt, granular chemicals, pulp, animal feed, grains, cement, construction chemicals, coal, stone and corn.

CH is a digital and fully electronic scale used in weighing cattle and sheep. The weight of live animals is an essential element, which should be kept under strict control in order to achieve the desired performance in today s livestock fattening industry. The scale platform is capable of weighing one cattle at a time. The platform features a cage-like banister with two gates enabling entry and exit of the animal. CH is bundled with a digital-display indicator, which can either be mounted on an indicator column or used indoors as a desktop indicator. Once animal is placed on the weighing platform, the entry and exit gates are closed in order to prevent any movement. It is possible to print the measured weight if the scale is connected to a printer. In addition to printing each animal s weight individually, the system can also print the total weight of the entire herd at the end of the weighing operation.

Quality control has always been the most important element in today s competitive environment. It is not a desired situation that a product, which has been packed and will be sent to the customer after a long process to be missing or excessive, in terms of both the consumer rights and the company s expenses. At this final stage of production, Esit Octaline Check Weigher checks whether the weight of the packed product is, in line with accepted value weight of the product. Esit Octaline Check Weigher is composed of weighing belt and digital control terminal. Weighing belt runs automatically by integrating in existing belt system The products are weighed while they are passing on the weighing belt, the packages with non-conforming weight or number of parts are determined. Audio and visual warning system runs for non-confirming packages; furthermore there are some rejection options such as marking, piston separation, tilting etc. for sorting such products out of the belt. Esit Octaline Check Weigher digital control unit is capable of reporting. Reports taken with regards to the production quantities and missing package quantities are assessed as important data during production control in the company

No represented companies found.

The company has no registered brand information.

TR

TR